- +39 049 900 62 11

- info@gruppocommit.it

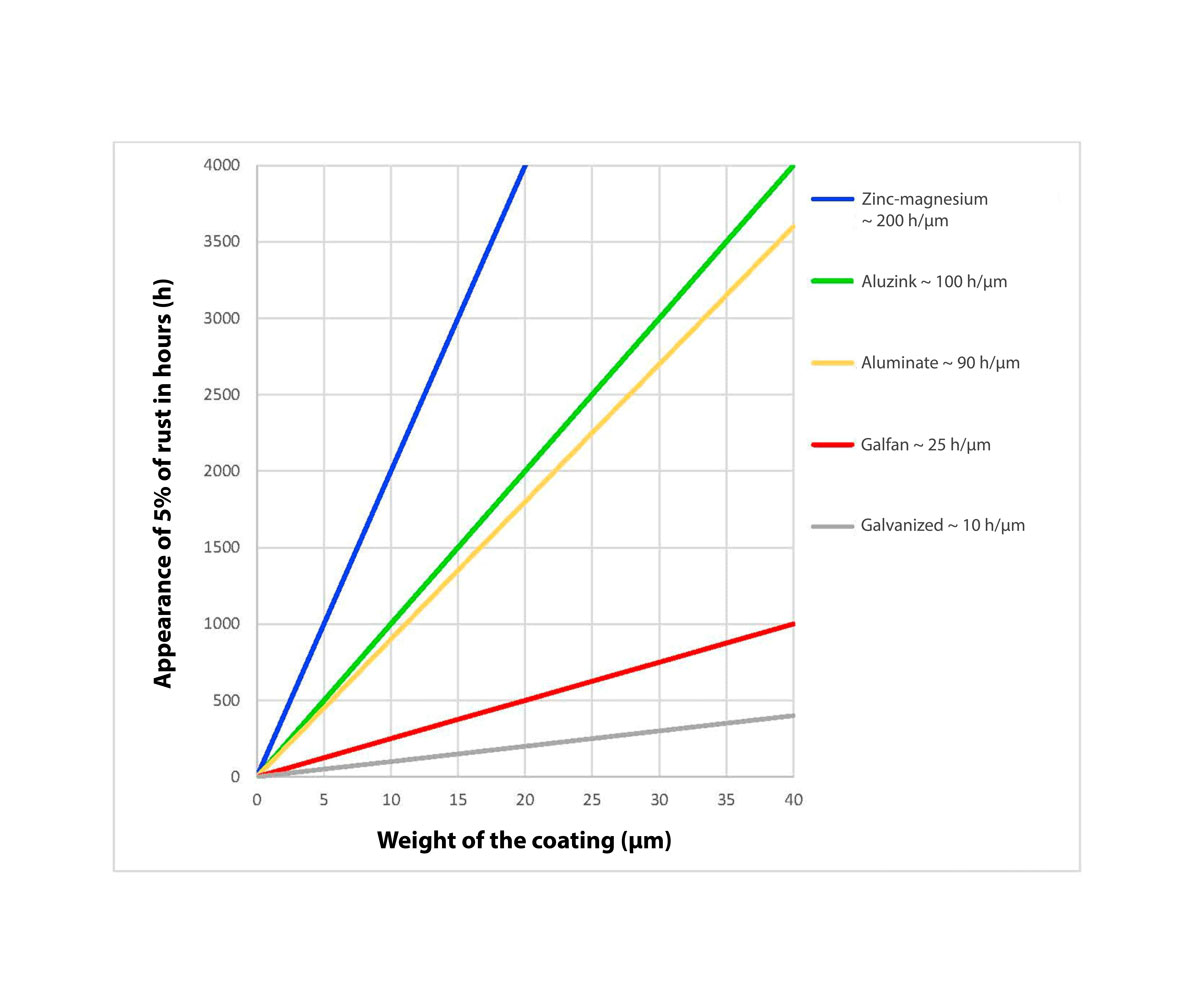

These products consist of a steel substrate over which a coating consisting of aluminum (55%) zinc (43.4%) and silica (1.6%) is applied by continuous hot dipping. Their main characteristic lies in their excellent corrosion resistance: several studies have shown that these steels, with the same coating thickness, have five times the resistance in salt spray than hot-dip galvanized steels. In addition, these products have a particularly pleasing appearance, excellent light and heat reflectivity, and remarkable abrasion resistance.

In acidic environments (such as urban or marine), the surface remains unaffected up to 315°C. Conversely, use in basic pH atmospheres and on livestock farms is not recommended.

| Name | Type of coating | Yield strength | Rupture | Elongation | Plastic deformation ratio | Cracking | |

| Quality | Type of coating | Re MPag | Rm MPag | A80 % min | r90 min | n90 min | |

| DX51D | +Z, +ZF, +ZA, +ZM, +AZ, +AS | – | 270 to 500 | 22 | – | – | |

| DX52D | +Z, +ZF, +ZA, +ZM, +AZ, +AS | 140 to 300 | 270 to 420 | 26 | – | – | |

| DX53D | +Z, +ZF, +ZA, +ZM, +AZ, +AS | 140 to 260 | 270 to 380 | 30 | – | – | |

| DX54D | +Z, +ZA | 120 to 220 | 260 to 350 | 36 | 1,6 | 0,18 | |

| DX54D | +ZF, +ZM | 120 to 220 | 260 to 350 | 34 | 1,4 | 0,18 | |

| DX54D | +AZ | 120 to 220 | 260 to 350 | 36 | – | – | |

| DX54D | +AS | 120 to 220 | 260 to 350 | 34 | 1,4 | 0,18 | |

| DX55D | +AS | 140 to 240 | 270 to 370 | 30 | – | – | |

| DX56D | +Z, +ZA | 120 to 180 | 260 to 350 | 39 | 1,9 | 0,21 | |

| DX56D | +ZF, +ZM | 120 to 180 | 260 to 350 | 37 | 1,7 | 0,2 | |

| DX56D | +AZ, +AS | 120 to 180 | 260 to 350 | 39 | 1,7 | 0,2 | |

| DX57D | +Z, +ZA | 120 to 170 | 260 to 350 | 41 | 2,1 | 0,22 | |

| DX57D | +ZF, +ZM | 120 to 170 | 260 to 350 | 39 | 1,9 | 0,21 | |

| DX57D | +AS | 120 to 170 | 260 to 350 | 41 | 1,9 | 0,21 | |

| g 1MPa = 1N/mm2 | |||||||

| Coating name | Minimum weight1) | Typical values of coating thickness per side in the single spot test | Density | ||

| g/m2 | μm | ||||

| Triple spot test | Single spot test | Typical value | Range | ||

| Peso del rivestimento di alluminio-zinco (AZ) | |||||

| AZ100 | 100 | 85 | 13 | 9-19 | 3,8 |

| AZ150 | 150 | 130 | 20 | 15-27 | |

| AZ185 | 185 | 160 | 25 | 19-33 | |

| 1) The g/m2 include both surfaces | |||||

Aluzinc® AZ150 | Galvanized Z275 | Advantages of Aluzinc® | ||||

thickness | surface | weight coating | surface | weight coating | ||

mm | m2/ton | kg/ton | m2/ton | kg/ton | m2 | % |

0.40 | 337.2 | 53.3 | 322.9 | 93.32 | 14.3 | 4.4 |

0.45 | 298 | 47.1 | 286.8 | 82.89 | 11.2 | 3.9 |

0.50 | 267 | 42.2 | 257.9 | 74.53 | 9.1 | 3.5 |

0.55 | 241.8 | 38.2 | 234.4 | 67.74 | 7.4 | 3.2 |

0.60 | 220.9 | 34.9 | 214.7 | 62.05 | 6.2 | 2.9 |

0.65 | 203.4 | 32.1 | 198.1 | 57.25 | 5.3 | 2.7 |

0.70 | 188.5 | 29.8 | 183.9 | 53.15 | 4.6 | 2.5 |

0.75 | 175.6 | 27.7 | 171.6 | 49.59 | 4 | 2.3 |

0.80 | 164.3 | 26 | 160.8 | 46.47 | 3.5 | 2.2 |

0.90 | 145.6 | 23 | 142.9 | 41.3 | 2.7 | 1.9 |

1.00 | 130.8 | 20.7 | 128.6 | 37.17 | 2.2 | 1.7 |

1.20 | 108.6 | 17.2 | 107.1 | 30.95 | 1.5 | 1.4 |

1.25 | 104.2 | 16.5 | 102.8 | 29.71 | 1.4 | 1.4 |

1.50 | 86.6 | 13.7 | 85.6 | 24.74 | 1 | 1.2 |

1.70 | 76.3 | 12.1 | 75.5 | 21.82 | 0.8 | 1.1 |

2.00 | 64.7 | 10.2 | 64.2 | 18.55 | 0.5 | 0.8 |

A | Minor imperfections - such as small honeycombs, variations in grain size, dark spots, light scratches, and passivation spots - are possible |

B | It is obtained through skinpass. Small imperfections - such as scratches due to skinpass, streaks, irregularities (not cavities) - are possible with this kind of surface |

C | It is obtained through skinpass. The best surface does not harm the apparent uniformity of a high color finish class; the other surface must be at least type B |

C | Chemical passivation, traditionally chromium-based; also available free of trivalent chromium, in compliance with the RoHS Directive; greenish residues may remain on the surface that do not alter product characteristics |

O | Oiling using oils that can be removed during greasing without compromising the coating |

CO | Combination of oiling and chemical passivation to enhance the protective effect against corrosion |

S | Organic passivation, commercially referred to as AFP (Anti Finger Print) or SPT (Resin Coating), consisting of a polymer film containing corrosion inhibitors; available free of hexavalent chromium; improves corrosion protection, prevents fingerprinting, facilitates sliding during processing, and acts as a primer during painting |

P | Phosphating, particularly suitable for the application of a subsequent layer of paint |

PO | Combination of phosphating and oiling to improve formability |

U | Without any protection, under the customer’s responsibility |

• Heating

• Household appliances

• Radiation

• Air ducts

• Panels

• Computers

• Electrical cabinets

• Roofing tiles

They can be supplied with special requirements for coating finish, surface appearance and surface protection.

The coating finish exhibits a normal, shiny, silver-colored stellation resulting from the growth of aluminum-zinc crystals during solidification.

The surface appearance can be type A, B or C; unless otherwise requested at the time of order, the material is supplied with appearance A.

Whatever the type of protection, it is very important that during transportation and storage the materials avoid contact with moisture or water as much as possible and be kept in a dry environment.

These steels are available in different ranges of properties, from commercial (DX51D) to deep drawing (DX54D, DX56D), to structural application products (S250GD) and high-strength grades (HX340LAD).

Commit Siderurgica SPA

Via dell’industria, 23

35030 Veggiano (PD)

VAT no. 01958150284

Commit Metalli SRL

Via volta, 69

35030 Veggiano (PD)

VAT no. 04678270283